Your shopping cart is empty!

Acoustic foam - a tool for effective acoustics

- 05 January 2018 15:29:44

- Reviews: 0

- Views: 13045

-

How does acoustic foam work?

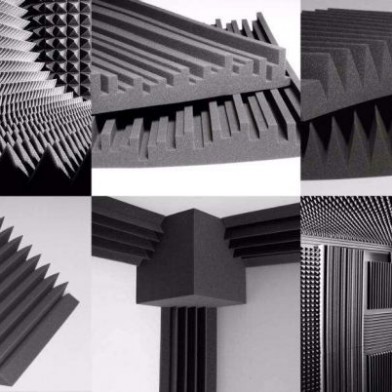

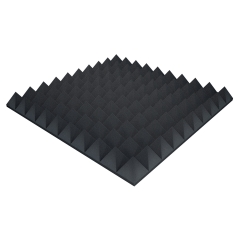

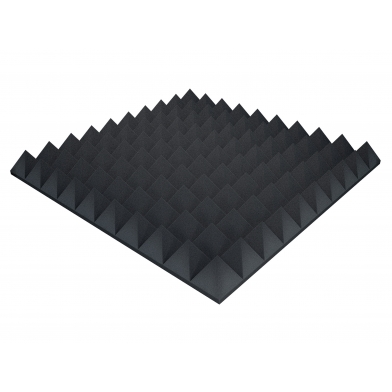

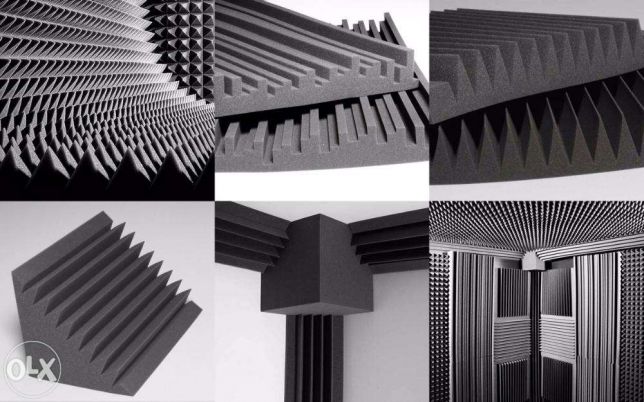

Due to its porous composition, acoustic foam rubber is perfectly able to dampen most of the acoustic vibrations, converting vibrational energy into thermal energy. Only a small part of the fluctuations is reflected back. Acoustic panels made of foam rubber with a figured relief allow you to achieve a better result of acoustic correction than flat ones. Shaped obstacles in the path of an acoustic wave more effectively scatter it in the environment and thus provide the best results of acoustic correction of the room.Scope of application

Acoustic foam rubber is used due to its excellent sound absorption properties. It is able to maintain its geometric dimensions well and is easily installed in any hard-to-reach places. Acoustic foam rubber is a material for the manufacture of designer acoustic panels that fit perfectly into the interior due to:- a wide range of panel types,

- their color palette

- the ability to produce an exclusive relief of acoustic panels.

- recording studios,

- TV studios

- studio radio,

- concert halls,

- restaurants,

- temples,

- theaters,

- cinemas,

- home cinemas,

- conference rooms,

- meeting rooms,

- and many other types of objects

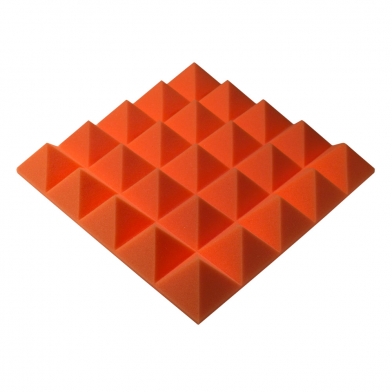

The difference in the shapes and sizes of foam rubber

Acoustic foam panels are available in various types of rails, sizes and thicknesses. Each surface shape can vary greatly in its sound absorption coefficient at different sound frequency bands. These characteristics are taken into account when calculating the room acoustics. The sharp contours of the foam will help you disperse sound and absorb more energy through repeated bouncing off the walls. In turn, flatter forms are less prone to damage and deformation. Effective absorption in the sound range also depends on the shape. All these parameters also depend on the density and thickness of the material. The thicker the material, the more distance the sound wave will overcome, which will lose its intensity along the way. When choosing suitable models of products from acoustic foam rubber, for the optimal solution of your problem, you should take into account the following parameters:

Acoustic foam panels are available in various types of rails, sizes and thicknesses. Each surface shape can vary greatly in its sound absorption coefficient at different sound frequency bands. These characteristics are taken into account when calculating the room acoustics. The sharp contours of the foam will help you disperse sound and absorb more energy through repeated bouncing off the walls. In turn, flatter forms are less prone to damage and deformation. Effective absorption in the sound range also depends on the shape. All these parameters also depend on the density and thickness of the material. The thicker the material, the more distance the sound wave will overcome, which will lose its intensity along the way. When choosing suitable models of products from acoustic foam rubber, for the optimal solution of your problem, you should take into account the following parameters:

- layout of the room and its dimensions, protrusions of walls, ventilation, etc.,

- size and placement of objects in this room,

- placement of people in the room,

- parameters of sound sources, their placement and modes of operation,

- external acoustic factors.

Benefits of acoustic foam

Acoustic foam rubber is made of polyurethane foam, which is odorless and harmless to the human body, unlike mineral wool and many other materials used in acoustic correction. Acoustic foam retains its shape well under significant loads during transportation or under extreme conditions of use, such as in the gym. Foam rubber can also be a non-combustible material, which is a weighty argument in terms of fire safety. Acoustic foam rubber does not require additional materials in the installation, it is enough just to attach it to the desired place with glue or double-sided tape. Interior decoration can be done by absolutely anyone without dust, noise and other inconveniences.How to choose the right acoustic foam?

When choosing a product model made of acoustic foam rubber, it is recommended to contact an acoustics specialist to determine the type, number of products and their optimal layout. Acoustic foam rubber products can perform not only their direct function, but also become a design element. Color, shape and patterns can be chosen to your taste, taking into account the interior of the room. Despite the small weight of the products, we recommend ordering delivery from the online store due to their large overall dimensions, which are not always able to accommodate a passenger car.Featured products

Showing 1 to 3 of 3 (1 Pages)