VIBRATION FASTENING

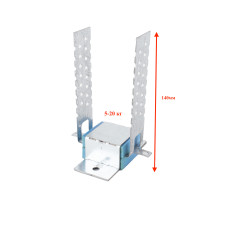

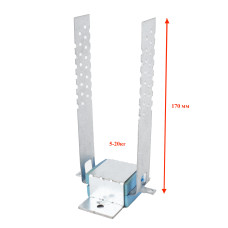

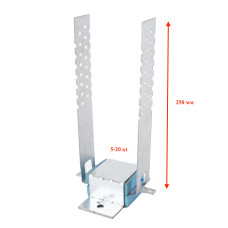

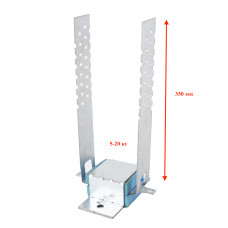

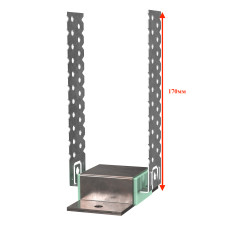

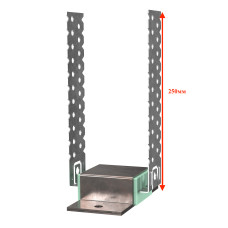

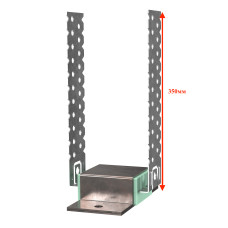

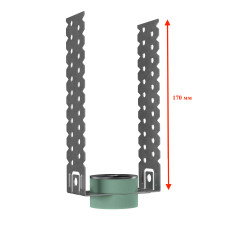

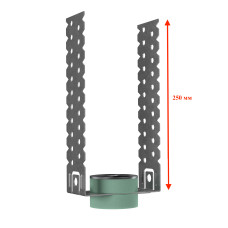

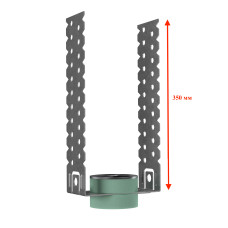

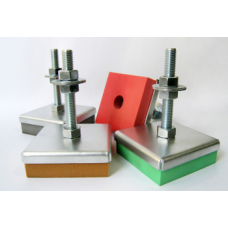

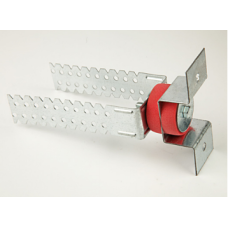

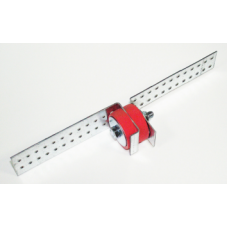

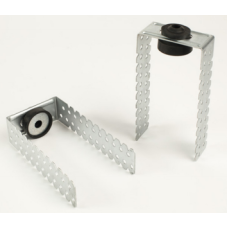

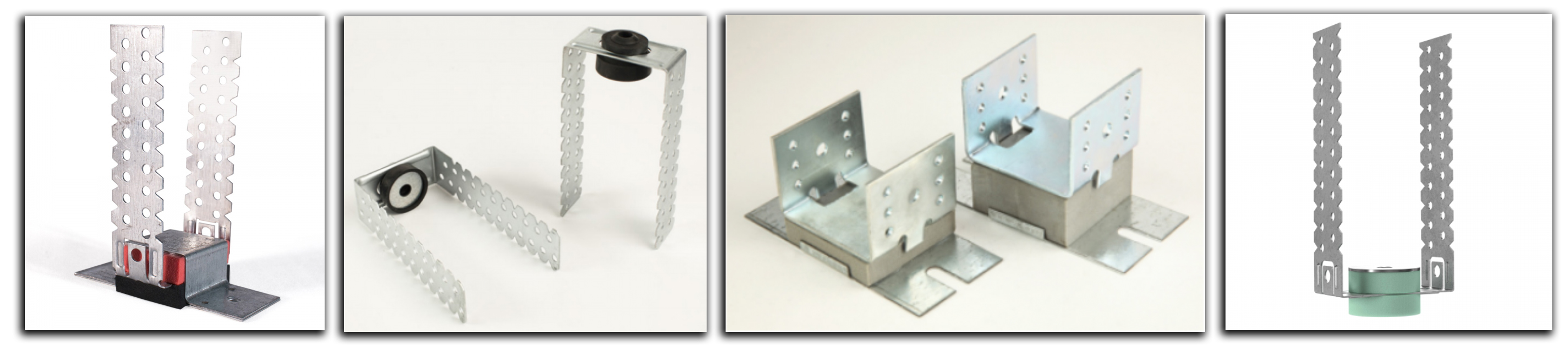

Along with various types of vibration-isolating membranes and plates, vibration fasteners are very effectively used to create high-quality protection of a room or equipment from vibration. Vibration isolating hangers and fasteners are required in order to untie the frame from the soundproof surface. Using vibro fasteners or vibro suspensions, a metal frame for plasterboard ceilings, walls and cladding is mounted to the supporting structures of the building. These vibration isolating fasteners are used in frame structures of walls and ceilings to protect the premises from airborne noise and vibration. The profile system is mounted on a straight perforated suspension, which is located between two anti-vibration pads made of a special elastomeric material and does not have rigid connections with the metal frame of the product, due to this, high vibration isolation rates are achieved. Vibonet is used as a vibration mount in the suspension, the unique properties of which make it possible to achieve high vibration isolation performance, unlike similar analogues.

Main features of vibration fasteners and anti-vibration fasteners

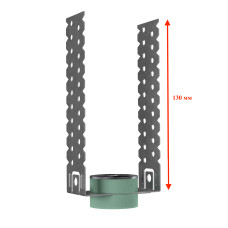

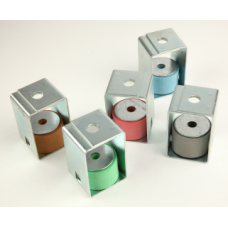

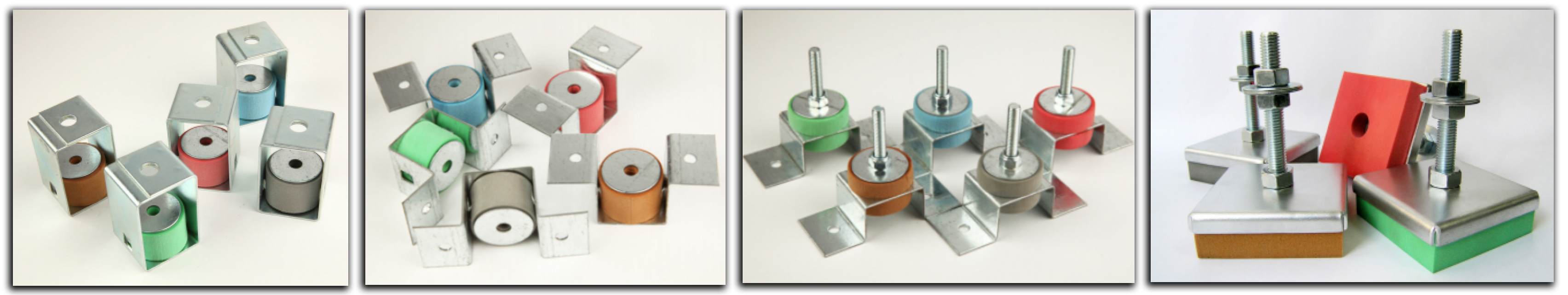

Vibration-insulating wall fastening, as well as a U-shaped sound-proof suspension, provide reliable fastening of the structure, they are used to dampen and reduce the transmission of vibration from the ceiling from the upper floors. The frame of the vibration mounts is made of corrosion-resistant, anodized steel. By using a vibration hanger, vibration isolator or vibration damper, you improve the acoustic performance of the soundproofing system much better than with conventional rigid mounts. It is worth dividing into two types of vibration fasteners, those used on walls and those used on ceilings. The VibroNet universal vibration mount is ideal for both walls and ceilings. Vibonet anti-vibration mounts are made from durable galvanized steel. As an elastic element, a highly effective vibration-isolating material is used - microporous polyurethane elastomer, specially made to solve problems in the field of vibration protection Macsound 360. High-quality metal parts of Vibonet mounts are designed for long-term operation. Elastic elements allow to withstand the maximum peak loads, far exceeding their natural working range. Among the vibration mounts, we can distinguish such fasteners as:

- Anti-vibration mounts for soundproofing ceilings and walls Ecosound-VibroNet MP-30

- Anti-vibration mounts for soundproofing walls and ceilings VibroNet А2

- Vibrofix UNI anti-vibration mounts

- Vibrofix BOX anti-vibration mounts

- Anti-vibration mounts-vibration isolation of the floor Vibrofix Floor

- Anti-vibration mounts for ceiling soundproofing-Vibrofix P

- Anti-vibration universal mounts-Vibrofix Protector

Most vibration fasteners use Macsound 360 material. Macsound 360 is a quality elastomer from which the vibration decoupling itself is made in vibration fasteners.

Scope of vibration fasteners and anti-vibration fasteners

The main task of vibration fasteners and anti-vibration fasteners is to eliminate the negative impact of vibration in the room, despite the fact that the source of vibration can be both outside the room and inside it. This type of fasteners and vibration suspensions are used to create vibration isolation of various types of premises, vibration isolation of industrial equipment and vibration isolation of rail tracks. In rooms, vibration mounts are used for walls, as well as a U-shaped noise-absorbing suspension or a direct anti-vibration suspension. For a variety of equipment, vibration isolators or spring vibration isolators are used. Vibratory fasteners are installed on walls, ceilings or floors. To understand what type of fasteners you need for your premises or equipment, it is best to seek the help of qualified professionals. You can find such specialists by calling tel. 067-647-7694 or using the Callback service. Our specialists will answer all your questions and concerns regarding the choice of material and its further use in creating vibration protection. We are always happy to help you!

Vibrating fasteners

Vibrating fasteners, also known as vibro fasteners, are a crucial component of many mechanical and structural systems. These specialized fasteners are designed to withstand high levels of vibration and shock, making them ideal for use in applications where traditional fasteners may fail. In the USA, vibro fasteners are widely used in industries such as aerospace, automotive, construction, and manufacturing.

One of the key benefits of vibro fasteners is their ability to maintain a secure hold in the face of constant vibration. In applications where machinery or equipment is subjected to high levels of vibration, such as aircraft engines or construction equipment, traditional fasteners can loosen over time, leading to equipment failure. Vibro fasteners are specifically engineered to resist these vibrations, ensuring that they stay securely in place.

Another advantage of vibro fasteners is their ease of installation. While some specialized fasteners require complex installation procedures, vibro fasteners are designed for quick and easy installation, making them a cost-effective solution for many applications. This ease of installation can save both time and money, making vibro fasteners a popular choice for manufacturers and contractors across the USA.

In addition to their resistance to vibration and ease of installation, vibro fasteners are also highly durable. Made from high-quality materials such as stainless steel or titanium, these fasteners are designed to withstand the toughest conditions, from extreme temperatures to corrosive environments. This durability ensures that vibro fasteners have a long service life, making them a reliable choice for critical applications.

Overall, vibro fasteners are an important component of many mechanical and structural systems in the USA. Their ability to withstand high levels of vibration, ease of installation, and durability make them a popular choice for industries where reliability is paramount. Whether it's securing aircraft components, building bridges, or assembling manufacturing equipment, vibro fasteners play a crucial role in ensuring the safety and efficiency of a wide range of applications.