Along with protecting the room from the penetration of extraneous noise and sounds, it is also necessary to protect the room from the negative effects of vibration, especially if your room is located near large highways, railways and other sources that can cause vibration. This applies not only to residential premises, but also to various industrial productions, with a high level of noise and vibration, where it is necessary to protect not from the external influence of noise and vibration, but vice versa, in order, firstly, to minimize the occurrence of vibration in the production processes (to produce vibration isolation of equipment), and secondly, to minimize the release of noise and vibration from the room in which they are formed. Vibration is also generated during the movement of vehicles (railways and motorways). Therefore, there is a whole range of measures to protect buildings and structures, equipment, instruments and people from the harmful effects of vibration. Vibration isolation can be divided into several areas, regarding where and with what it is carried out. There are four main types of vibration isolation: vibration isolation of premises, vibration isolation of equipment, vibration isolation of vehicles, vibration isolation of rail tracks.

Vibration isolation of premises

When vibration isolation of buildings and premises, two types of vibration isolation are produced. Vibration isolation is produced in the vibration source or in the vibration receiver. In most cases, it is very difficult to isolate vibration at the source of its occurrence, if it is not located in the building itself. Therefore, if we talk about vibration isolation of rooms, then first of all, this is vibration isolation of the room itself, as a vibration receiver. Vibration isolation of the receiver is a technical solution for acoustic breaking of vibrations directly in the place of their impact. There are four types of vibration isolation of a building:

1. Full plane support under building foundation with side mats. This vibration isolation has a very simple design and installation. Allows you to reach low natural frequencies. There is no need to change the structure of the building.

2. Strip support of the foundation of the building or its elements. With this type of vibration isolation, it is supported on the bases in the form of strips. It allows acoustic decoupling of the vibrations of the floors of the building. The minimum amount of materials when installing this vibration isolation. Achieving very low natural frequencies.

3. Point support of the building foundation or its elements. Reliance is made on point bases. Allows you to perform vibration isolation of buildings on pile foundations. It is possible to achieve very low natural frequencies.

4. Wall in the ground between the existing vibration source and receiver. With this type of vibration isolation, vibrations are trapped along the transmission path. Vibration isolation is made in the process of reconstruction.

Macsound 360 is also used in this case. Macsound 360 is an elastomer from which the vibration decoupler itself is made in vibration fasteners.

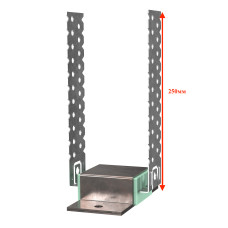

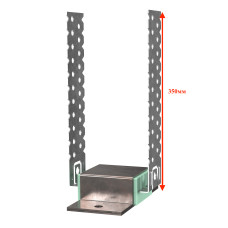

Vibration isolation equipment

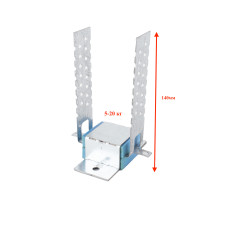

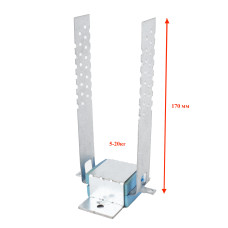

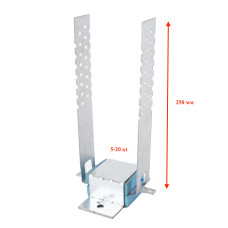

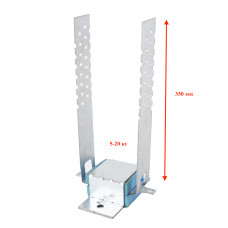

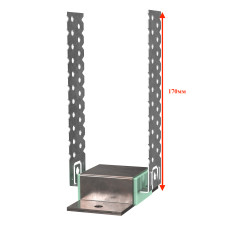

For vibration isolation of equipment, anti-vibration mounts and Vibonet supports are used. These fasteners and supports are used for vibration isolation of engineering equipment, pipelines of engineering networks, ventilation ducts, installation of compressor, ventilation and pumping units, as well as vibration isolation of the bases of heating boilers, diesel generators and special industrial equipment. The features of Vibonet mounts allow them to cover a wide range of workloads, thus these mounts can be used for vibration isolation of various types of engineering equipment.

Vibonet anti-vibration mounts are made from durable galvanized steel. As an elastic element, a highly effective vibration-isolating material is used - a microporous polyurethane elastomer, specially made to solve problems in the field of Macsound 360 vibration protection. Strong metal parts of Vibonet mounts are designed for long-term operation. Elastic elements can withstand peak loads that are much higher than their operating range.

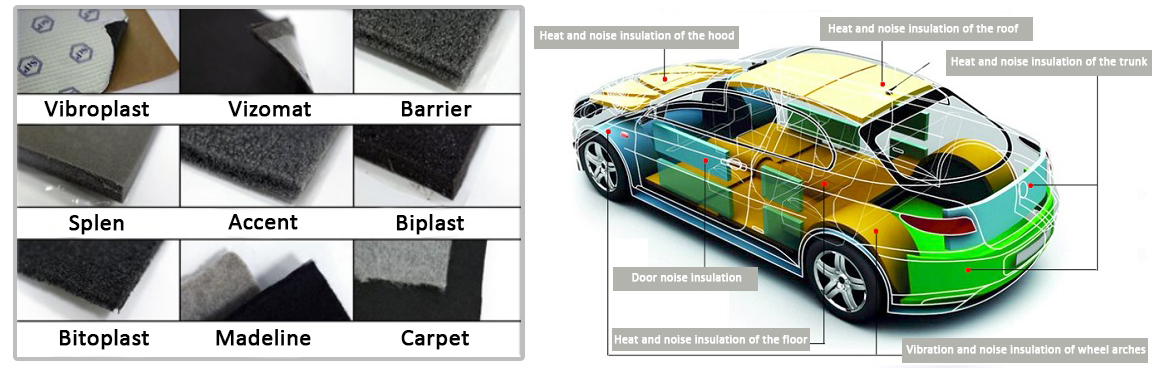

Vibration isolation of vehicles

Vibration isolation in road transport provides peace and quiet while traveling on bad, uneven roads with poor quality pavement or pits. Movement in the car will be accompanied by various sounds and vibrations. Such phenomena can greatly irritate both the driver and passengers. Due to the constant noise, fatigue from the trip appears faster, headaches and other unpleasant phenomena occur. Therefore, in order to make the train more comfortable, it is necessary to make the vibration isolation of the car.

In luxury cars, factory vibration isolation is initially present. That is why trips on such machines are more comfortable. The production of more budget cars does not provide for the use of high-quality insulation, so car owners have to buy and install vibration-proof materials on their own.

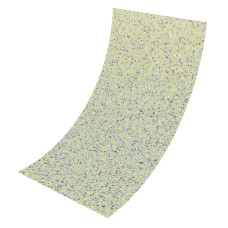

Today there is a wide range of vibration isolation components. Noise-vibration isolation is divided into two groups: one that fights sounds, and one that prevents vibrations. To achieve the highest possible level of silence in the cabin, it is recommended to use both types. Sometimes, in addition to vibration isolation, bitumen thermal insulation is additionally used.

Vibration isolation of rail tracks

Another type of vibration isolation is the vibration isolation of rail tracks. In this case, rail transport is a source of vibration, which is transmitted to nearby buildings. Therefore, in order to isolate this source of vibration, while creating a sufficient level of elasticity of the rail track, thereby reducing the wear of materials, it is necessary to perform vibration isolation of the rail tracks. Products and systems with high elasticity for vibration isolation, firstly, will significantly reduce the costs arising from the wear of the materials from which the rails are made, and secondly, they will minimize the formation of vibration. There are many options for vibration isolation of rail tracks, which allow you to cover all the components of the rail cover:

- supports of mass-spring systems

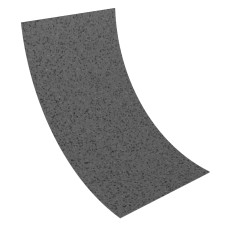

- subballast mats

- sleeper shoe inserts

- sleeper pads

- rail fasteners

- rail pads

- solid rail supports

- rail gauge fillers (crossing decks)

Vibration isolation

Vibration isolation is a crucial aspect of building design and construction that is often overlooked. It refers to the process of reducing the transmission of vibrations from one structure to another, or from one part of a structure to another. This is important because vibrations can cause discomfort, damage to equipment, and even structural failure if not properly managed.

There are three main types of vibration isolation: floor vibration isolation, wall vibration isolation, and ceiling vibration isolation. Each type serves a specific purpose and requires different techniques to effectively reduce vibrations.

In the USA, vibration isolation is particularly important in commercial buildings, industrial facilities, and residential homes. In commercial buildings, vibrations from heavy machinery or HVAC systems can disrupt employees and affect productivity. In industrial facilities, vibrations can damage sensitive equipment and machinery, leading to costly repairs and downtime. In residential homes, vibrations from nearby roads or railways can cause discomfort and disturb the peace and quiet of homeowners.

Floor vibration isolation is a common technique used to reduce vibrations in buildings. This is typically achieved by installing vibration isolation pads or mounts between the floor and the building's foundation. These pads absorb and dampen vibrations, preventing them from traveling through the floor and causing disturbances. Floor vibration isolation is especially important in buildings with heavy machinery or equipment that generate significant vibrations.

Wall vibration isolation is another important aspect of vibration control. Walls can transmit vibrations from one room to another, causing discomfort for occupants. To reduce this transmission, vibration isolation materials such as resilient channels or soundproofing insulation can be installed within the walls. These materials absorb vibrations and prevent them from traveling through the walls, creating a more comfortable and peaceful environment.

Ceiling vibration isolation is also crucial in buildings with multiple levels. Vibrations from the floor above can easily transfer through the ceiling, causing disturbances in the rooms below. To prevent this, vibration isolation materials such as ceiling hangers or isolators can be installed to absorb and dampen vibrations. This helps to create a quieter and more comfortable environment for occupants on all levels of the building.

In conclusion, vibration isolation is an important aspect of building design and construction that should not be overlooked. By implementing floor vibration isolation, wall vibration isolation, and ceiling vibration isolation techniques, building owners can create a more comfortable and efficient environment for occupants. In the USA, where buildings are often large and complex, proper vibration isolation is essential to ensure the safety and well-being of occupants. By investing in quality vibration isolation materials and techniques, building owners can prevent costly damage and disruptions caused by unwanted vibrations.