Vibration isolation membranes

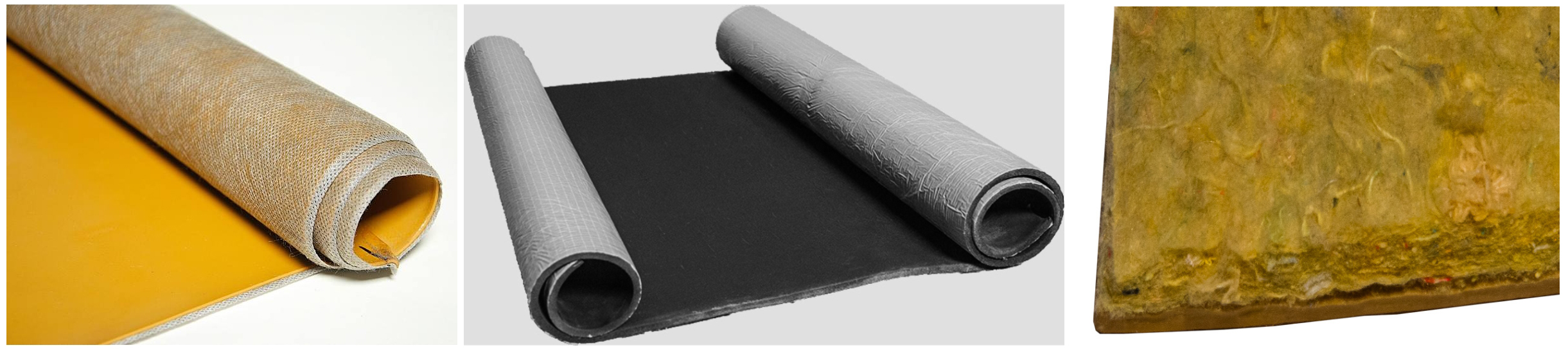

If you need to make high-quality vibration isolation of a room, you need to thoroughly approach the choice of the material that will be used for this type of isolation. Using only high-quality materials, in accordance with the standards and norms regarding this type of product, you can get a 100% guaranteed result. For vibration isolation of rooms, acoustic membranes and acoustic plates are mainly used. Vibration isolation membranes allow not only to provide protection against the penetration of extraneous sounds and noise into the room, but also protect against the negative impact caused by vibration. It can be used both indoors and outdoors, in combination with other soundproofing materials.

Features of the anti-vibration membrane

Vibration isolation membranes and plates come in different sizes and different compositions of the components from which they are made. When creating vibration isolating membranes, soundproof acoustic materials are used, especially cast or foamed material, sometimes with the addition of felt. Vibration-isolating membranes and plates are used in the form of an elastic gasket like a spring. The characteristics of this spring gasket can be adapted according to the requirements of the application, design or construction method by varying the type of material, layer thickness and contact surface. With a structure characterized by a unique combination of open and closed cells, anti-vibration membranes combine the properties of both a spring that creates an ideal reflection and a damper that creates an ideal absorption. It is the combination of these two qualities - reflection and absorption - that makes it possible to produce vibration isolation of the room with the highest quality.

Among the models of vibration-isolating membranes and plates, it is worth highlighting such models as:

- Acoustic membrane Black Flex 10 mm 1mx1m reinforced

- Membrane with felt heavy Ecosound MTV-30 1900 kg/m.cube-1mx1m

- Acoustic membrane White Flex 10 mm 1mx1m reinforced

- Heavy vibration isolation membrane Ecosound MT-28 1900 kg/m.cube-1mx1m

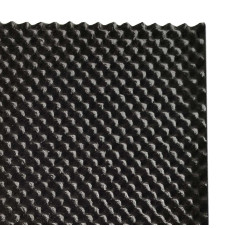

- Acoustic plate Ecosound Macsound Prof thickness 5mm 1mx0.5m color graphite black

- Acoustic vibration isolation plate Ecosound Macsound Prof 1mx0.5mx10mm color graphite black

- Acoustic vibration isolation plate Ecosound Macsound Prof Wave 1mx0.5mx30mm-color graphite black

In addition, these membranes and panels, when creating vibration isolation protection, are combined with Vibonet anti-vibration mounts. These fasteners are made of durable galvanized steel. As an elastic element, a highly effective vibration-isolating material is used - a microporous polyurethane elastomer, specially designed to solve problems in the field of Macsound 360 vibration protection. Strong metal parts of Vibonet mounts are designed for long-term operation. Resilient and strong elements allow to withstand the maximum peak loads, far exceeding their maximum operating range.

Physical and chemical properties of anti-vibration membranes

All anti-vibration membranes and plates have fairly good properties and characteristics. This is what makes them more efficient and practical. It is worth highlighting among them the following features and properties:

- High dynamic efficiency

- Small dependence on amplitudes

- Low dependence on frequencies

- Flammability class E according to EN 13501-1

- High resistance to chemicals and oils

- High mechanical strength (tensile strength, elongation at break)

- Large range of different materials with special stiffness for different loads

Before choosing which particular model of anti-vibration membranes is needed to isolate your premises or equipment, you will receive qualified advice from a professional specialist on a device to protect against the negative effects of vibration. Call us at tel. 067-647-7694 or use the "Callback" service and get answers to all your questions regarding the choice of material and its further use when creating vibration protection. We are always happy to help you!

Vibration isolation membranes

Vibration isolation membranes play a crucial role in minimizing the transmission of vibrations from one structure to another. These membranes are designed to absorb and dampen vibrations, providing a quieter and more comfortable environment for building occupants. In this article, we will delve into the importance of vibration isolation membranes, with a focus on their use in the vibration isolation of walls.

In the United States, the use of vibration isolation membranes has become increasingly prevalent in both residential and commercial buildings. With the growing emphasis on sustainability and environmental responsibility, architects and engineers are turning to innovative solutions to reduce noise pollution and improve overall building performance.

Vibration isolation membranes are typically made from materials such as rubber, foam, or cork, which are known for their ability to absorb vibrations. When installed between the structural elements of a building, such as walls, floors, and ceilings, these membranes help to prevent the transfer of vibrations from one area to another.

In the context of vibration isolation of walls, membranes are often placed between the wall studs and the drywall or plasterboard. This helps to reduce the transmission of vibrations from external sources, such as nearby traffic or machinery, as well as internal sources like HVAC systems or plumbing. By effectively isolating the walls, building occupants can enjoy a quieter and more peaceful living or working environment.

In addition to noise reduction, vibration isolation membranes also offer other benefits. They can help to protect sensitive equipment or machinery from the harmful effects of vibrations, prolonging their lifespan and reducing maintenance costs. Furthermore, by minimizing vibrations, these membranes can improve the overall structural integrity of a building, reducing the risk of damage or failure over time.

As building codes and regulations continue to evolve, the use of vibration isolation membranes is expected to become more widespread across the United States. Architects and engineers are increasingly looking for ways to enhance the comfort and safety of building occupants, and vibration isolation membranes offer a cost-effective and efficient solution to address these concerns.

In conclusion, vibration isolation membranes play a crucial role in the vibration isolation of walls, helping to create a more comfortable and peaceful indoor environment. As the demand for sustainable and high-performance buildings continues to grow, the use of these membranes is expected to increase, making them an essential component of modern construction practices. By incorporating vibration isolation membranes into building designs, architects and engineers can effectively address noise pollution and ensure the longevity and safety of structures for years to come.