Noise insulation of a boiler room, production hall and other similar noise sources

- 17 October 2022 23:19:06

- Reviews: 0

- Views: 294

-

Since the construction uses pressed acoustic board combined with acoustic foam for soundproofing, both of these components can withstand some humidity, especially if they are ventilated, but this will definitely not be good if they are directly exposed to rain and water.

Many of you are probably now thinking "oh yes, but I have a million pipes and tubes in my boiler room / unit." Foam rubber is easy to work with, it can be cut and cut well, and if you have a lot of them and it is complex, then you can leave a piece open, as in one work, where we left almost the entire top open, because the pipes went up.

Each unit, pump, boiler, etc. produce different heat, so the question arises how much free space to leave, i.e. what size to make a box and how much and where to make ventilation, respectively, ventilation windows.

Unfortunately, I cannot answer this question, pumps, generators or boilers are not my area, and there are many types of them. However, the seller or manufacturer must provide you with this information.

Your device must be placed on a flexible mat or silent blocks

Otherwise, it resonates directly into the floor, which then spreads throughout the building. Devices that are attached directly to the wall also have poor insulation. Vibrations go straight into the wall and spread further through the house with gradual losses. Acoustic pressed board can easily be a flexible mat.

Ideal shock absorber compound

Instead of OSB boards, it is more reasonable to use our new material, namely eco soundproofing board, which has much better attenuation values than OSB board.

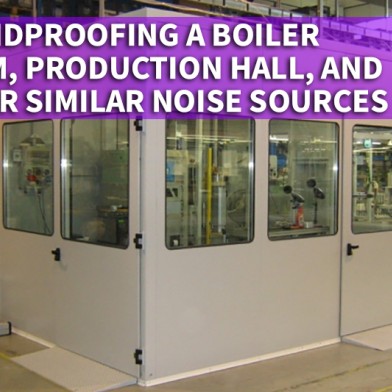

Pressed boards should ideally form a continuous surface on the inside. Every point interrupted by, for example, a stubborn box structure or every poorly connected corner represents a weakness. I hope it will be clear from the picture.

If the box is smaller, there is no need to make a design for lighting. For large ones, it is necessary to make a structure, for example, from wood shavings or aluminum profiles.

The correct decision is to either install the boards on the structure from the inside or from the outside, short and good, so that the structure does not interfere with the integrity and good connection of the pressed boards.